Relative Grade

|

Grade

|

U.K.

|

U.S.A.

|

Russia

|

Standard

|

|

1J22

|

Permendur

|

Supermendur

HiperCo50

|

50КФ

|

GB/T14986-2008

|

Grade and Chemical Composition (see Table 1)

Table

1 Grade and Chemical Composition

|

Grade

|

Chemical Composition (%)

|

|

C≤

|

Mn≤

|

Si≤

|

P≤

|

S≤

|

Cu≤

|

Ni≤

|

Co

|

V

|

Fe

|

|

lJ22

|

0.04

|

0.30

|

0.30

|

0.020

|

0.020

|

0.20

|

0.50

|

49.0~51.0

|

0.80~1.80

|

Balance

|

Physical Property (see Table2 & Table3)

Table2

Physical Property

|

Grade

|

Resistivity /(μΩ·m)

|

Density

/(g/cm3)

|

Curie point

/°C

|

Magnetostriction

Cofficient/(×l0-6)

|

Tensile Strength

/MPa

|

|

Unannealed

|

Annealed

|

|

1J22

|

0.40

|

8.20

|

980

|

60~100

|

1325

|

490

|

Table 3 Magnetic Property

|

Grade

|

Forms

|

Magnetic Flux Density At Different Magnetic Field

Strength

|

Coercivity /Hc/(A/m)≤

|

|

B400

|

B800

|

B1600

|

B2400

|

B4000

|

B8000

|

|

T

|

|

≥

|

|

1J22

|

Cold Rolled strips

|

1.70

|

1.90

|

2.00

|

2.10

|

2.20

|

2.25

|

110

|

|

Wires,

Rods,Forgings,Billets

|

1.60

|

1.70

|

1.80

|

2.05

|

2.15

|

2.20

|

144

|

Description:

Hiperco 50A alloy is a soft magnetic alloy which has been used primarily as

magnetic core material in electrical core material in electrical equipment

requiring high permeability values at very high magnetic flux densities.The

magnetic characteristics of this alloy permit weight reduction, reduction of

copper turns, and insulation in the end product when compared to other magnetic

alloys having lower permeabilities in the same magnetic field range.

Physical Properties

Specific

gravity.........................................8.20

Density

lb/cu in ................................................... 0.295

kg/cu m ................................................... 8200

Electrical resistivity

ohms c/mf ................................................ 253

microhm-mm ........................................... 420

Mean Coefficient of

Thermal Expansion

|

Temperature

|

Coefficient

|

|

68°F to

|

20°C to

|

10(-6)/°F

|

10(-6)/°C

|

|

392

752

1112

1472

|

200

400

600

800

|

5.28

5.61

5.83

6.28

|

9.5

10.1

10.5

11.3

|

Curie Temperature

°F ........................................................... 1710

°C ............................................................ 932

Saturation induction at

H = 250 oersteds(kilogausses) .................. 23

H = 19.9 at/m(Telsa) ................................ 2.3

Saturation magnetostriction

change in unit length x 10(-6) .................. 60

Workability

Machinability

The following charts include typical machining parameters used to machine

Hiperco 50A alloy. The data listed should be used as a guide for initial

machine setup only.

|

High Speed Tools

|

|

Turning-

Single Point

And Box Tools

|

High Speed Tools

|

SFPM

IPR

|

25-30

.003-.010

|

|

Carbide Tools

|

SFPM

IPR

|

70-90

.020-.007

|

|

Turning

And

Forming

Tool Width

|

Cut-Off

Tool

Width

|

1/16"

|

SFPM

IPR

|

25

.001

|

|

1/8"

|

SFPM

IPR

|

25

.002

|

|

1/4"

|

SFPM

IPR

|

25

.003

|

|

Form

Tool

Width

|

1/2"

|

SFPM

IPR

|

25

.004

|

|

1"

|

SFPM

IPR

|

25

.0025

|

|

1-1/2"

|

SFPM

IPR

|

25

.002

|

|

Drilling

|

Drill

Dia.

|

3/8"

|

SFPM

IPR

|

30

.005

|

|

3/4"

|

SFPM

IPR

|

30

.010

|

|

Reaming

|

Under 1/2"

|

SFPM

IPR

|

65

.005

|

|

Over 1/2"

|

SFPM

IPR

|

65

.010

|

|

Die Threading

|

T.P.I

|

3-7

|

SFPM

|

8

|

|

8-15

|

SFPM

|

10

|

|

Over 16

|

SFPM

|

15

|

|

Tapping

|

T.P.I

|

3-7

|

SFPM

|

6

|

|

8-15

|

SFPM

|

7

|

|

16-24

|

SFPM

|

11

|

|

Over 25

|

SFPM

|

15

|

|

Milling

|

SFPM

IPR

|

20-35

.001-.005

|

|

Broaching

|

|

SFPM

|

8-15

|

|

Chip Load

|

IPT

|

.002

|

When using carbide tools, surface speed

feet/minute (SFPM) can be increased between 2 and 3 times over the high speed

suggestions. Feeds can be increased between 50 and 100%.

Figures used for all metal removal

operations covered are average. On certain work, the nature of the part may

require adjustment of speeds and feeds. Each job has to be developed for best

production results with optimum tool life. Speeds or feeds should be increased

or decreased in small steps.

Heat Treatment

When selecting a

heat treating temperature for the application, two factors should be

considered:

1. For best magnetic soft characteristics,

select the highest suggested temperature.

2. If the application requires specific

mechanical properties higher than that produced when employing the highest

temperature, select the temperature that will provide desired mechanical

properties.

As temperature

decreases, magnetic properties become less magnetic soft. Heat treating

temperature for best soft magnetic properties should be 1625°F +/- 25°F (885°C

+/- 15°C).Do not exceed 1652°F(900°C).

The heat treating

atmosphere used must be nonoxiding and noncarburizing. Atmospheres such as dry

hydrogen or high vacuum are suggested. Time at temperature should be two to

four hours. Cool at a rate of nominally 180 to 360°F (100 to 200°C) per hour to

a temperature of least 700°F(370°C), then cool naturally to room temperature

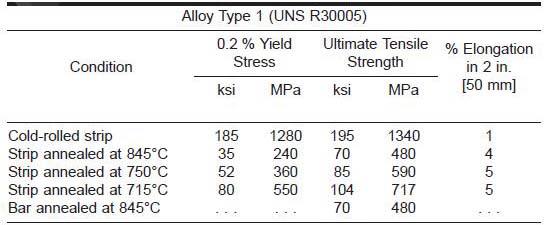

Typical Mechanical Properties

Effect of Heat

Treating Temperature on Hardness - Hiperco 50A alloy

|

Temperature

|

Hardness Rockwell B

|

|

°F

|

°C

|

|

1558

1598

1625

1692

|

843

870

885

925

|

94

89

97

92(poor magnetic properties)

|

Specification:

Sheet/Plate, Bar/Rod/Coil

Size Range:

*Sheet---thickness 0.10mm~0.50mm, width:10.0~210.0mm,Condition: cold rolled,

bright

*Plate---thickness 3.5mm~40.0mm,width:≤300mm,Condition: cold rolled, hot rolled

*Bar---Dia 8.0mm~Dia 32.0mm,length:≤2000mm,Condition:hot rolled,burnished

Dia 32.0mm~Dia

150.0mm,length:≤1000mm,Condition:hot forging,peeled, turned

Note: we could do any other

products with specified technical standard, say,

ASTM,SAE,DIN,S.E.W.,JIS,ISO,IEC,NF,BS,ΓОСТ.PLS contact us for more information:

Tel: +86-29-89396652 or e-mail us at: Sales@xaleipeng.com