Elastic Component Alloys (3J1 and 3J53) (YB/T5256-1993)

*Ni-Span Alloy C-902, AMS 5225, UNS N09902,

(Ni42CrTiAl),Chinese 3J53

|

Grade

|

Relative Grade

|

|

Russia

|

U.S.A.

|

Japan

|

Germany

|

U.K.

|

|

3J1

|

36НХТЮ

ЭП702

|

|

|

|

|

|

3J53

|

42НХТЮ

Н41ХТ

|

Ni-Span

C902

Elinvar

Extra

|

Sumispan-3

EL-3

|

Ni-Span

C

|

Ni-Span

C

|

Grade and Chemical

Composition (see Table 1)

Table 1 Grade and Chemical Composition

|

Grade

|

Chemical Composition (%)

|

|

C

|

Mn

|

Si

|

P

|

S

|

Ni

|

Cr

|

Ti

|

A1

|

Fe

|

|

≤

|

|

3J1

|

0.05

|

1.00

|

0.80

|

0.020

|

0.020

|

34.5~36.5

|

11.5~13.0

|

2.70~3.20

|

1.00~1.80

|

Bal

|

|

3J53

|

0.05

|

0.80

|

0.80

|

0.020

|

0.020

|

41.5~43.0

|

5.20~5.80

|

2.30~2.70

|

0.50~0.80

|

Bal

|

NOTE: The size and shape

must comply with the standard of GB/T15001for “elastic alloys”.

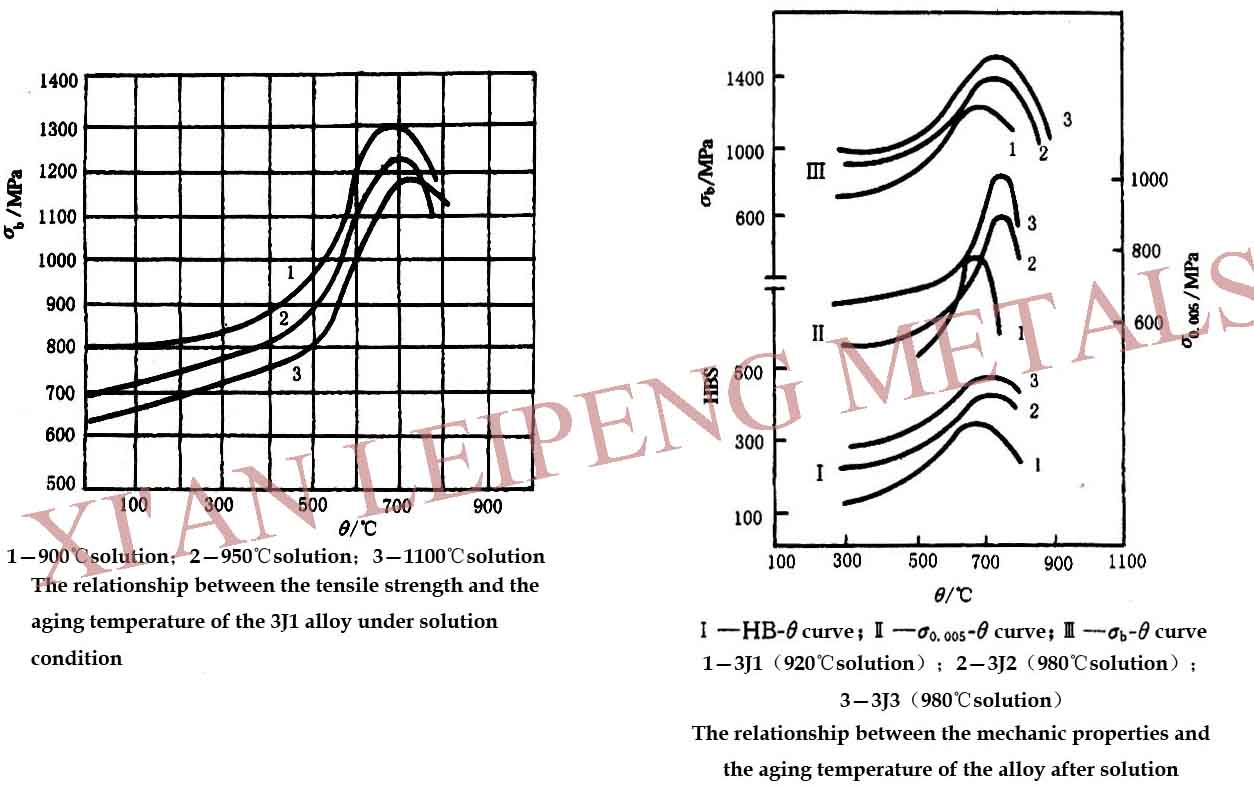

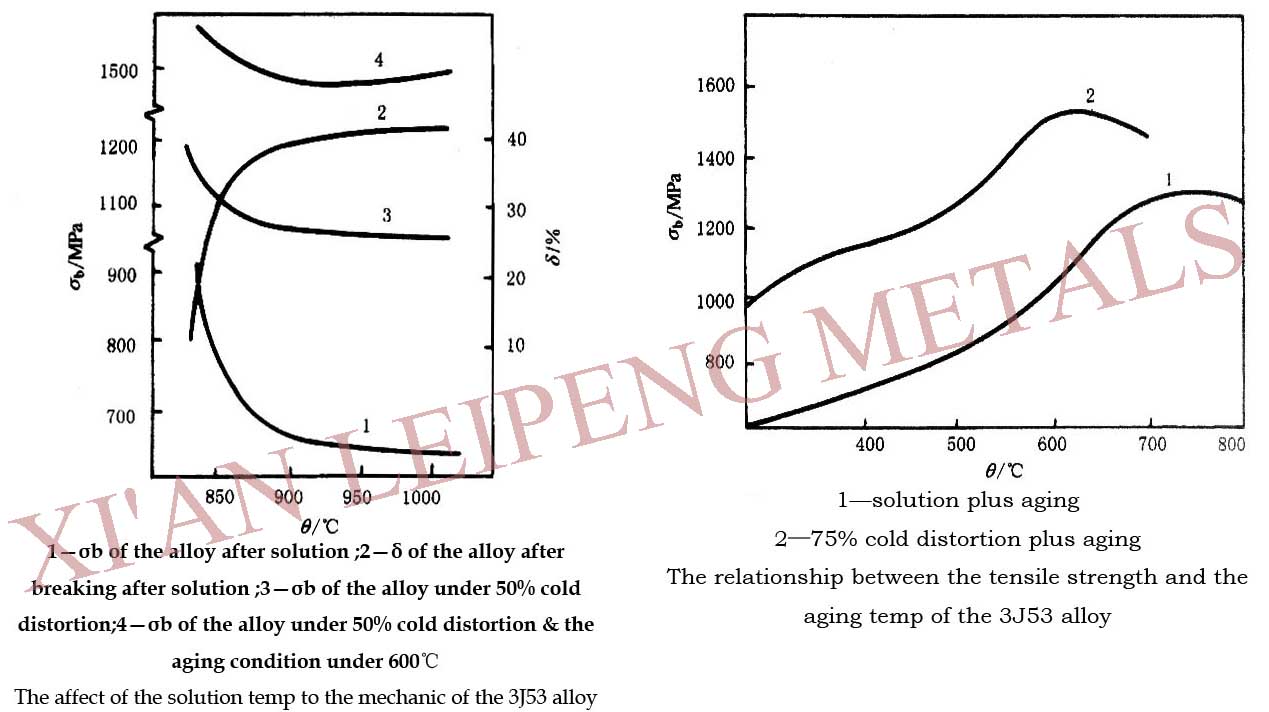

Mechanical

Property (see Table 2—Table4)

Table 2 Mechanical

Property (for the delivery statue)

|

Grade

|

Shape

|

Delivery State

|

Thickness&Diameter

/mm

|

Tensile Strength

ób/Mpa

|

Elongationδ(%)≥

|

|

3J1

|

Strip

|

Annealed

|

0.20~0.50

|

<980

|

20

|

|

Wire

|

Cold Drawn

|

0.20~3.00

|

>980

|

|

|

3J53

|

Strip

|

Annealed

|

0.20~0.50

|

<885

|

20

|

|

Wire

|

Cold Drawn

|

0.20~3.00

|

>930

|

|

Table 3 Mechanical Property(after heat treatment)

|

Grade

|

Shape

|

Delivery State

|

Thickness&Diameter

/mm

|

Tensile Strength

ób/Mpa

|

Elongation δ(%)

|

|

≥

|

|

3J1

|

Strip

|

Cold Rolled

|

0.20~2.50

|

1375

|

5

|

|

Annealed

|

0.20~1.00

|

1175

|

8

|

|

Wire

|

Cold Drawn

|

0.50~5.00

|

1470

|

5

|

|

Bar

|

Cold Drawn

|

3.0~18.0

|

1375

|

5

|

|

Pipe& flatspring

|

Hot Rolled & Hot Forged

|

6.0~25.0

|

1175

|

1O

|

|

3J53

|

Strip

|

Cold Rolled

|

0.20~2.50

|

1225

|

5

|

|

Annealed

|

0.20~1.00

|

1080

|

8

|

|

Wire

|

Cold Drawn

|

0.50、5.00

|

1375

|

5

|

|

Bar

|

Cold Drawn

|

3.0~18.0

|

1325

|

5

|

|

Pipe& Flatspring

|

Hot Rolled & Hot Forged

|

6.0~25.0

|

1080

|

10

|

Table

4 Yield Strength (after heat treatment)

|

Grade

|

Delivery State

|

Thickness

/mm

|

Yield Strength

/MPa

|

|

3J1

|

Cold Rolled

|

0.50~2.50

|

980

|

|

Annealed

|

0.50~1.00

|

735

|

|

3J53

|

Cold Rolled

|

0.50~2.50

|

885

|

|

Annealed

|

0.50~1.00

|

685

|

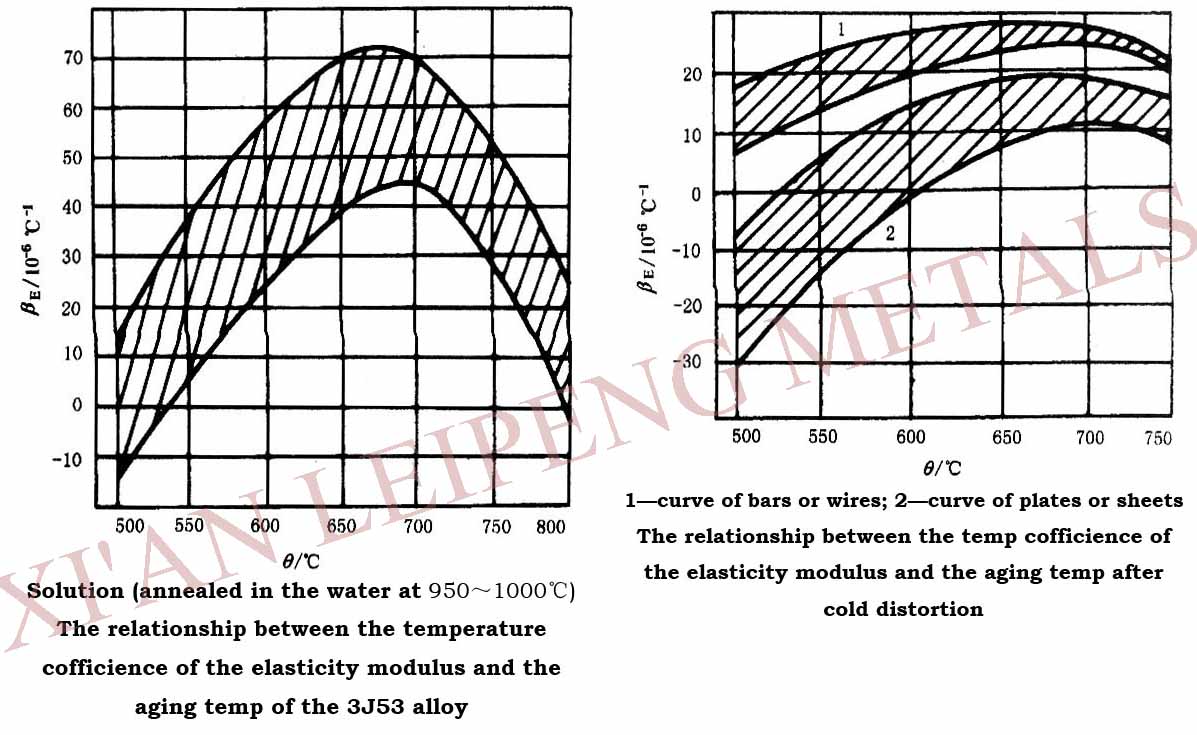

Physical Property (see Table5&Table6)

Table 5 physical property mechanical

property (after aging)

|

Item

|

3J1

|

3J53

|

|

Modulus of elasticity (E/MPa)

|

186500~206000

|

176500~191000

|

|

Shear elasticity (G/MPa)

|

68500~78500

|

63500~73500

|

|

Desinty (g/cm3)

|

8.0

|

8.0

|

|

Mean coefficient of linear

expansion20-100°C/(10-6/K)

|

|

8.5

|

|

Saturation induction density (B600/T)

|

|

0.7

|

|

Resistivity ρ /(μΩ·m)

|

1.02

|

1.1

|

|

Magnetic Rate k/106

|

150~250

|

|

|

Vickers hardness (HV)

|

400~480

|

350-450

|

Note: The K value is the value of the centimeter

gram second system.

Table

6 the temperature coefficient of the Modulus

of elasticity

|

Aging Temperature/℃

|

the temperature

coefficient of the Modulus of elasticity

βE/(10-6/℃)(-60~80℃)

|

|

Cold Rolling

|

Annealed

|

|

500

|

-38~-15

|

+18~+12

|

|

550

|

-22~0

|

+10~+35

|

|

600

|

-10~+10

|

+35~+55

|

|

650

|

0~+20

|

+42~+64

|

|

700

|

0~+20

|

+40~+60

|

|

750

|

-4~+16

|

+28~+50

|

Note: we could do any other

products with specified technical standard, say,

ASTM,SAE,DIN,S.E.W.,JIS,ISO,IEC,NF,BS,ΓОСТ.PLS contact us for more information:

Tel: +86-29-89396652 or e-mail us at: Sales@xaleipeng.com