Shock-proof

& Wear Resistant axle-centre alloy(YB/T5243-1993)

Relative

Grade:40ХНЮ-ВИ,ЭП793 Russia

Grade and Chemical Composition (see

Table1)

Table1 Grade and Chemical Composition

|

Grade

|

Chemical Composition (%)

|

|

C

|

P

|

S

|

Mn

|

Si

|

Fe

|

Cr

|

A1

|

Ce①

|

Ni

|

|

≤

|

|

3J40

|

0.03

|

0.010

|

0.010

|

0.10

|

0.20

|

0.50

|

39.0~41.0

|

3.30~3.50

|

0.10~0.2

|

Bal

|

① Based on addition.

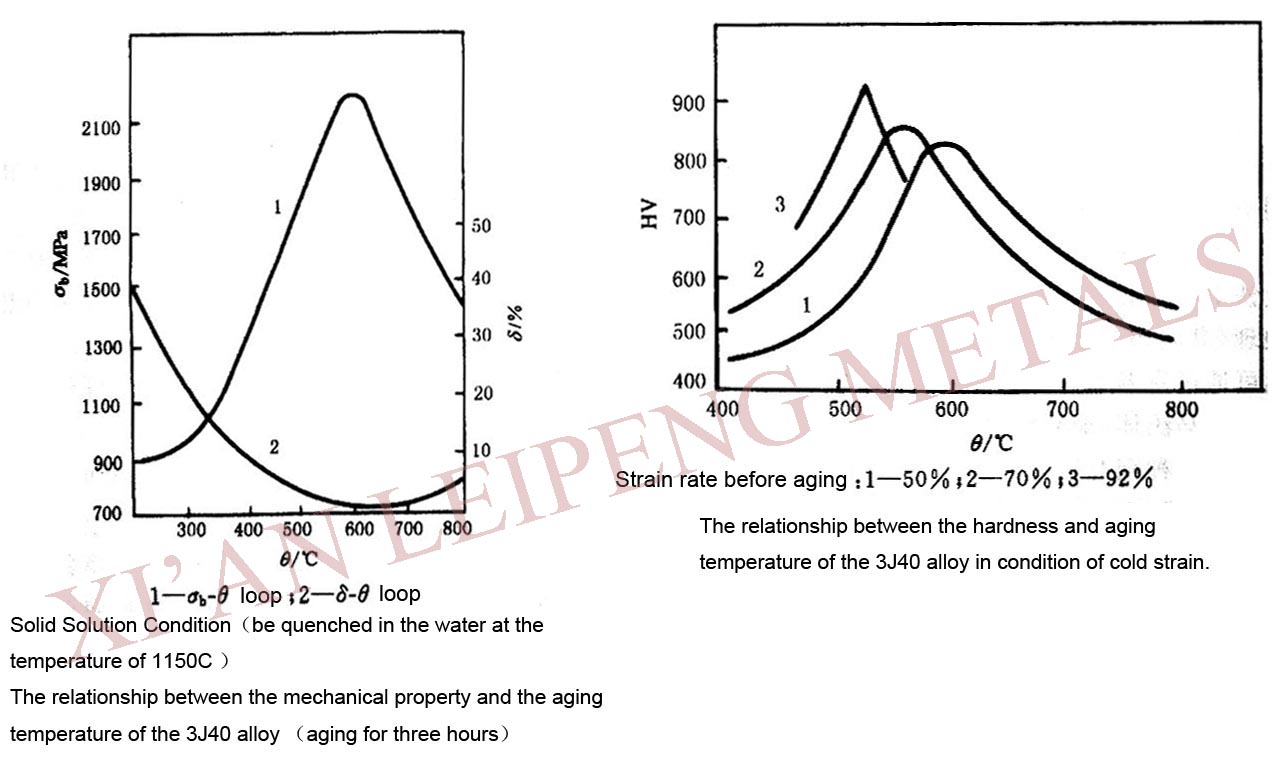

Mechanical Property (see

Table 2)

Table 2 Mechanical Property

|

Statue

|

Vickers Hardness/ HV

|

Commended Heat Treatment

|

Bend Test

The radius

of the mandrel is twice as the diameter of the alloy

|

|

I

|

Ⅱ

|

Ⅲ

|

|

|

Cold Drawing

|

450~510

|

|

Bend 90 degrees. No cracks and

broken on the outside of the bending

|

|

Cold Drawn &

Aging

|

780~830

|

>830~880

|

>880

|

480~540°C

Keep warm for 5h

|

|

NOTE: 1、The default hardness

classification of the alloy wire in cold drawing & aging status is class

II.

Physical Property (see Table 3—Table 5)

Table 3 Coefficient

of Linear Expansion

|

State

|

Coefficient

of Linear Expansion/(10-6/K)

|

|

20~55℃

|

20~100℃

|

20~200℃

|

20~300℃

|

20~400℃

|

20~500℃

|

|

Solid Solution

|

12.2~12.7

|

12.4~12.5

|

12.6~12.8

|

13.0~13.1

|

13.5~13.6

|

13.8~14.0

|

|

Solid Solution&aging

|

11.0~11.5

|

11.9~12.0

|

12.0~12.2

|

12.4~12.5

|

12.7~12.8

|

13.1~13.3

|

|

Cold drawn & aging

|

11.6

|

12.0

|

12.1

|

12.4

|

12.8

|

13.3

|

Table

4 Modulus

of Elasticity & Frequency Temperature Coefficient

|

State

|

Modulus of

Elasticity

|

Temperature

Coefficient βf/(10-6℃)

|

Mechanical Quality

Factor Q20℃

|

|

20~-40℃

|

20~100℃

|

|

Solid Solution +80% Strain Rate

|

176500~196000

|

|

|

|

|

Solid Solution +80% Strain Rate+Aging

5h

|

225500~235500

|

-103~-106

|

-104~-110

|

49000~51000

|

Table 5 Magnetic Susceptibility & Resistivity

|

State

|

Magnetic Susceptibility

|

Resistivity

/(μΩ?m)

|

Density

/(g/cm3)

|

|

H=40KA/m

|

H:80KA/m

|

|

Solid Solution

|

3.5~4.5

|

3.5~4.6

|

|

7.6

|

|

Solid Solution+ Aging

|

3.8~4.0

|

2.4~4.2

|

|

|

|

Solid Solution+ Cold

Drawing

|

2.8~3.0

|

|

1.21

|

|

|

Solid Solution +69% Strain Rate+Aging

|

|

|

0.78

|

|

Corrosion

Resisting Property (See Table 5)

Table

5 Corrosion Resisting Property

|

State

|

Salt Fog Test

|

Long-time store in the air

|

|

Cold

Drawing+ Solid Solution+Aging

|

No

corrosion after 240 hours (Tested by the buyer per JB1606)

|

No corrosion

|

Usage: It is applied to produce the axle-centre

of instrument and meter as well as the

axle-centre of the staff

Note: we could do any other

products with specified technical standard, say,

ASTM,SAE,DIN,S.E.W.,JIS,ISO,IEC,NF,BS,ΓОСТ.PLS contact us for more information:

Tel: +86-29-89396652 or e-mail us at: Sales@xaleipeng.com