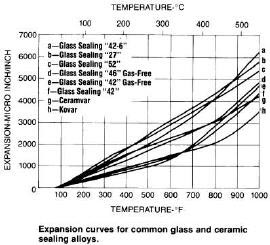

Glass sealed and controllled expansion alloys

*kovar alloy, ASTM F15, Nilo-K, UNS K94610 (FeNi29Co17),Chinese 4J29

* Specifications:ASTM F15; DIN 17745; S.E.W. 385; Werkstoff Nr. 1.3981; AFNOR NF A54-301

Similar Grades

|

Russia

|

U.S.A.

|

U.K.

|

Japan

|

France

|

Germany

|

|

29НК

|

Kovar

|

Nilo K

|

KV-1

|

Dilver P0

|

Vacon 12

|

|

29НК-ВИ

|

Rodar

Techallony Glasseal

29-17

|

Teleaseal

|

KV-2

KV-3

|

Dilver P1

|

Silvar 48

|

Grade & Chemical Composition (see Table

1)

Table

1 Grade & Chemical Composition

|

Grade

|

Chemical Composition (%)

|

|

C

|

P

|

S

|

Mn

|

Si

|

Cu

|

Cr

|

Mo

|

Ni

|

Co

|

Fe

|

|

≤

|

|

4J29

|

0.03

|

0.020

|

0.020

|

0.5

|

0.30

|

0.20

|

0.20

|

0.20

|

28.5~29.5

|

16.8~17.8

|

Bal

|

|

4J44

|

0.03

|

0.020

|

0.020

|

0.5

|

0.30

|

0.20

|

0.20

|

0.20

|

34.2~35.2

|

8.50~9.50

|

Bal

|

Notes:

1. The content of Al、Mg、Zr and Ti

should be no more than 0.10%,the

total content should be no more than 0.20%. Otherwise, the supplier’sPOand/or contract shall indicate clearly.

2. Under

condition that the average coefficient of the linear expansion meets the

requirements of the standard, the content of nickel and cobalt are allowed to

deviate from the stated range.

3. The shape and dimensions of the alloys are in

compliance with GB/T14985.

Mechanical Property (see table 2-table 4)

Table

2 Tensile Strength of Wire

|

Symbol

|

Status

|

Tensile Strength/MPa

|

|

R

|

Annealed

|

<585

|

|

1/4 I

|

1/4 hard

|

585~725

|

|

1/2 I

|

1/2 hard

|

655~795

|

|

3/4 I

|

3/4 hard

|

725~860

|

|

I

|

unannealed

|

>860

|

Table

3 Tensile Strength Of Strip

|

Symbol

|

Status

|

Tensile Strength/MPa

|

|

R

|

annealed

|

<570

|

|

1/4 I

|

1/4

unannealed

|

520~630

|

|

1/2 I

|

1/2

unannealed

|

590~700

|

|

3/4 I

|

3/4 unannealed

|

600~770

|

|

I

|

unannealed

|

>700

|

Table

4 Hardness of Deep Stamping Strips

|

State

|

Thickness

|

Hardness, Hv

|

|

Deep Stamping

|

>2.5mm

|

≤170

|

|

≤2.5mm

|

≤165

|

Physical Property (see Table 5

& Table 6)

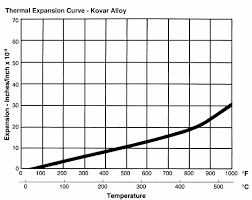

Table 5 Coefficient of Linear Expansion

|

Grade

|

Heat Treatment of the Samples

|

Average Coefficient of Linear Expansion

|

|

20~300℃

|

20~400℃

|

20~450°C

|

|

4J29

|

Heat to temperature of 900±20℃ in the hydrogen, hold

for 1h; re-heat to 1100±20℃, hold for 15 min.; cooled to200℃ at a rate less than 5℃/min

|

|

4.6~5.2

|

5.1~5.5①

|

|

4J44

|

4.3~5.1

|

4.6~5.2

|

|

①Upper limit is 5.6 for transistors.

Table 6 Typical Coefficient of Linear Expansion

|

Grade

|

Average Coefficient of Linear Expansion

|

|

20~200℃

|

20~300℃

|

20~400℃

|

20~450℃

|

20~500℃

|

20~600℃

|

20~700℃

|

20~800℃

|

|

4J29

|

5.9

|

5.3

|

5.1

|

5.3

|

6.2

|

7.8

|

9.2

|

10.2

|

|

4J44

|

4.9

|

4.6

|

4.9

|

5.9

|

6.8

|

8.7

|

|

|

NOTE: The values in the table are for

reference only.

Usage:

It is applied to hard glass-to-metal seals.

Applications

Kovar

alloy has been used for making hermetic seals with the harder Pyrex glasses and

ceramic materials.

This alloy has found wide application in power tubes, microwave tubes,

transistors and diodes. In intergrated circuits, it has been used for the flat

pack and the dual-in-line package.

Preparation for Sealing

All

degreased, fabricated Kovar alloy parts should be degassed and annealed in a

wet hydrogen atmosphere. Atmosphere is to be made moist by bubbling the

hydrogen through water at room temperature. Care must be taken to prevent

surface carbon pickup. Furnace should have a cooling chamber provided with the

same atmosphere.

Heating should be conducted within the 1540/2010°F temperature range. Time at

temperature should be approximately two hours for lowest temperature to 20

minutes for the highest temperature. Parts should then be transferred to the

cooling zone and held until below 570°F, then removed.

An oxide film on the metallic part is preferred for metal-to-hard glass

sealing. The best oxide film is thin and tightly adhering. The film can be

produced by heating the parts to 1200/1290°F in regular ambient atmosphere for

a time sufficient to form a dark gray to slight brown oxide.

Workability

Forging

The principal precaution to observe in forging is to heat quickly and avoid

soaking in the furnace. Long soaking may result in a checked surface due to

absorption of sulfur from the furnace atmosphere and/or oxide penetration. A

forging temperature of 2000/2150°F is preferred.

Coolant

It is important to control heat build up, the major cause of warpage. A

suggested coolant would be Cool Tool. Cool Tool contains fatty esters to reduce

friction in the cutting zone and a refrigerant to remove the heat generated by

friction between the cutting tool and work place.

Tooling

T-15 Alloy, such as Vasco Supreme-manufactured by Vanadium Alloys Company. M-3

Type 2, such as Van Cut Type 2-manufactured by Vanadium Alloys Company. Congo

manufactured by Braeburn.

For machining with carbide tools, a K-6 manufactured by Kennemetal, Firthie HA

manufactured by Firth Sterling, or #370 Carboloy could be used, or a K2S

manufactured by Kennemetal, or Firthie T-04 manufactured by Firth Sterling

would be satisfactory. One thing of prime importance is that all feathered or

wire edges should be removed from the tools. They should be kept in excellent

condition by repeated inspection.

Turning

If steel cutting tools are used, try a feed of approximately .010" to

.012" per revolution and a speed as high as 35/FPM could probably be

attained. Some of the angels on the cutting tools would be as follows:

-

End cutting edge

angle -Approximately 7°

-

Nose radius

-Approximately .005"

-

Side cutting edge

angle -Approximately 15°

-

Back rake

-Approximately 8°

-

Side rake

-Approximately 8°

When cutting off

high speed tools are better than carbide tools, and a feed of approximately

.001" per revolution should be used. The cutting tools should have a front

clearance of about 7° and a fairly big tip--larger than 25° would be helpful.

Drilling

When drilling a 3/16" diameter hole, a speed of about 40/FPM could

possibly be used, and the feed should be about .002" to .0025" per

revolution, for a 1/2" hole, approximately the same speed could be used

with a feed of about .004" to .005" per revolution. The drills should

be as short as possible, and it is desirable to make a thin web at the point by

conventional methods. By conventional methods, we mean do not notch or make a

crank shaft grinding. It is suggested that heavy web type drills with nitrided

or electrolyzed surfaces be used. The hole, of course, should be cleaned

frequently in order to remove the chips, which will gall, and also for cooling.

The drill should be ground to an included point angle of 118° to 120°

Reaming

Reaming speeds should be half the drill speed, but the feed should be about

three times the drill speed. It is suggested that the margin on the land should

be about .005" to .010", and that the chamfer should be .005" to

.010" and the chamfer angle about 30°. The tools should be as short as

possible, and have a slight face rake of about 5° to 8°.

Tapping

In tapping, a tap drill slightly larger than the standard drill recommended for

conventional threads should be used, because the metal will probably flow into

the cut. It is suggested that on automatic machines, a two or three fluted

tapping tool should be used. For taps below 3/16", the two fluted would be

best. Grind the face hook angle to 8° to 10°, and the tap should have a

.003" to .005" chamfered edge. If possible, if binding occurs in the

hole in tapping, the width of the land may be too great, and it is suggested

that the width of the heel be ground down. Again, it is suggested that nitrided

or electrolyzed tools be used. Speed should be about 20/FPM.

|

High Speed Tool*

|

|

Turning

And

Forming

|

Cut-Off

Tool

|

1/16"

|

SFM

FEED

|

65

.0010

|

|

1/8"

|

SFM

FEED

|

67

.0012

|

|

1/4"

|

SFM

FEED

|

69

.0016

|

|

Tool

Width

|

1/2"

|

SFM

FEED

|

67

.0012

|

|

1"

|

SFM

FEED

|

63

.0010

|

|

1-1/2"

|

SFM

FEED

|

63

.0009

|

|

Drilling

|

Drill

Dia.

|

3/8"

|

SFM

FEED

|

43

.0030

|

|

3/4"

|

SFM

FEED

|

45

.0036

|

|

Reaming

|

Under 1/2"

|

SFM

FEED

|

57

.003

|

|

Over 1/2"

|

SFM

FEED

|

57

.0045

|

|

Threading

|

T.P.I

|

3-7

8-15

|

SFM

SFM

|

8

10

|

|

Over 16

|

SFM

|

16

|

|

Tapping

|

T.P.I

|

3-7

8-15

16-24

|

SFM

SFM

SFM

|

6

7

11

|

|

Over 25

|

SFM

|

16

|

|

Milling

|

|

SFM

FEED

|

35-70

.002-.005

|

|

Broaching

|

|

SFM

FEED

|

8-12

.001-.005

|

|

Turning

Single Point

& Box Tools

|

High Speed Tools

|

SFM

FEED

|

60-65

.0029-.0043

|

|

Carbide Tools

|

SFM

FEED

|

160-215

.025-.080

|

*When using carbide tools, surface

speed feet/minute (SFM) can be increased between 2 and 3 times over the high

speed suggestions. Feeds can be increased between 50 and 100%.

Note: Figures used for all metal

removal operations covered are average. On certain work, the nature of the part

may require adjustment of speeds and feeds. Each job has to be developed for

best production results with optimum tool life. Speeds or feeds should be

increased or decreased in small steps.

The information and data presented

herein are typical or average values and are not a guarantee of maximum or

minimum values. Applications specifically suggested for material described

herein are made solely for the purpose of illustration to enable the reader to

make his own evaluation and are not intended as warranties, either express or

implied, of fitness for these or other purposes.

Specification:

Sheet/Plate, Bar/Rod/Wire/Coil,Capillary/Pipe/Tube

Size Range:

*Sheet---thickness 0.05mm~3.5mm, width:≤350mm,Condition: cold rolled, bright,

bright annealed

*Plate---thickness 3.5mm~40.0mm,width:≤300mm,Condition: cold rolled, hot

rolled, annealed

*Round Wire---Dia 0.05mm~Dia 5.0mm,Condition: cold drawn, bright, bright

annealed

*Flat Wire---Dia 0.5mm~Dia 5.0mm,length:≤1000mm,Condition:flat rolled, bright

annealed

*Bar---Dia 5.0mm~Dia 8.0mm,length:≤2000mm,Condition:cold drawn,bright, bright

annealed

Dia

8.0mm~Dia 32.0mm,length:≤2500mm,Condition:hot rolled,bright, bright annealed

Dia 32.0mm~Dia

180.0mm,length:≤1300mm,Condition:hot forging,peeled, turned, hot treated

Capillary---OD 8.0mm~1.0mm,ID 0.1mm~8.0mm,length:≤2500mm,Condition: cold drawn,

bright, bright annealed

Pipe---OD 120mm~8.0mm,ID 8.0mm~129mm,length:≤4000mm,Condition: cold drawn,

bright, bright annealed

Note: we could do any other

products with specified technical standard, say,

ASTM,SAE,DIN,S.E.W.,JIS,ISO,IEC,NF,BS,ΓОСТ.PLS contact us for more information:

Tel: +86-29-89396652 or e-mail us at: Sales@xaleipeng.com