Table 1

Chemical Composition

|

Grade

|

Chemical Composition (%)

|

|

Hiperco 27

UNS K92650

|

C

|

Mn

|

Si

|

P

|

S

|

Cr

|

Ni

|

V

|

Co

|

Fe

|

|

≤

|

26.5~28.5

|

Bal

|

|

0.025

|

0.35

|

0.35

|

0.015

|

0.015

|

0.75

|

0.75

|

0.35

|

Table 2 Physical

Property

|

Density

|

Mean CTE

|

Thermal Conductivity

|

Modulus of Elasticity (E)

|

Electrical Resistivity

|

Curie Temperature

|

|

7.95g/cm3

|

As Below pic

|

380.2

BTU-in/hr/ft/°F

|

24.0x 10 3ksi

|

114.0

ohm-cir-mil/ft

|

1700°F/927℃

|

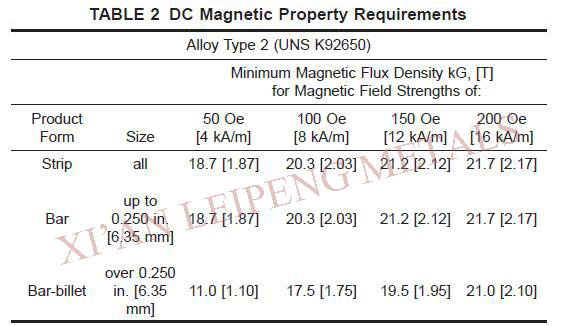

Table 3 Magnetic

Properties

- Saturation Magnetostriction= 36x 10-6 in/in

- Typical A.C. Magnetic Properties

- Typical D.C. Magnetic Properties

ASTM Standard Requested

Table 4 Heat

Treatment

All stamped laminations or

machined parts must be annealed after fabrication to develop acceptable

magnetic properties. Anneal parts at 1400/1652°F (760/900°C) for 2 to 4 hours

in dry hydrogen or vacuum and cool at 144/540°F (80/300°C) per hour until 572°F

(300°C). All parts must be cleaned prior to heat treating.

Table 5 Workability

Hot Working

Hiperco 27 alloy can be forged

from a furnace temperature of 2150°F (1177°C). Time at temperature should be

approximately 1 hour per inch of thickness. Forging can be conducted down to a

temperature of 1700°F (927°C). After forging, items can be air cooled.

Specification:

Sheet/Plate, Bar/Rod,Pipe,Billet

Size Range:

*Sheet---thickness 0.05mm~0.70mm, width:10.0~260.0mm,Condition: cold rolled,

bright

*Plate---thickness 3.5mm~40.0mm,width:10.0~260.0mm,Condition: cold rolled, hot

rolled

*Bar---Dia 8.0mm~Dia 32.0mm,length:≤2000mm,Condition:hot rolled,burnished

Dia

32.0mm~Dia 150.0mm,length:≤1000mm,Condition:hot forging,peeled, turned

Note: we could do any other

products with specified technical standard, say,

ASTM,SAE,DIN,S.E.W.,JIS,ISO,IEC,NF,BS,ΓОСТ.PLS contact us for more information:

Tel: +86-29-89396652 or e-mail us at: Sales@xaleipeng.com